| Available Bearings | Bearing Selector | Technical Info | New Products | |||

Mechanical Testing Laboratory - Dynaroll

MECHANICAL TESTING LAB

Assemblies Overview

Brochures

Applications

Assembly & Manufacturing

Quality Systems

Capabilities

Materials Management

Contract Manufacturing

Mechanical Testing Lab

Design Services

Quality Policy

MECHANICAL TESTING LABORATORY

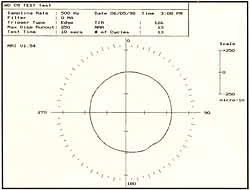

MICROTORQUE™ ANALYSIS OF BEARINGS AND PIVOTS

Starting,

average, peak-to-peak torque values

Starting,

average, peak-to-peak torque values

Bearing brinelling

Contamination

Raceway misalignment

Retainer drag

Lubricant fill and quality

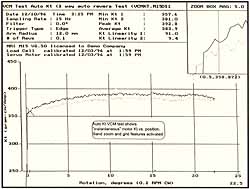

VOICE COIL TESTING

Bi-directional torque and Kt analysis

RESONANCE MEASUREMENT

Axial, radial (2-mode) measurement of resonance profile over 100Hz

to 20KHz.

RUNOUT

TIR and non-repetitive runout (NRR) to 10-7 inches (mm)

LUBRICANT ANALYSIS

Scanning IR

OTHER MEASUREMENTS

Roundness

Surface finish

Hardness

Automated part scanning (reverse-engineering)

Please contact a Dynaroll representative with your measurement

requirements. MicroTorque™ and resonance testers are commercially

available from Measurement Research, Inc.

|

|

TIR and NRR measurement. |

Voice coil motor Kt measurement |