| Available Bearings | Bearing Selector | Technical Info | New Products | |||

Quality Policy - Dynaroll

QUALITY POLICY

MECHANICAL ASSEMBLIES

Assemblies Overview

Brochures

Applications

Assembly & Manufacturing

Quality Systems

Capabilities

Materials Management

Contract Manufacturing

Mechanical Testing Lab

Design Services

Quality Policy

QUALITY POLICY

Dynaroll is completely committed

to continuously improving the quality of our products. This is an

easy statement to make, and is one which is often echoed by many

other companies. The difference is that, in today's world,

there are international standards for many aspects of quality control

that are used to qualify a company's true commitment to quality.

These standards are hard-earned and continuing compliance is regularly

audited by certified third-party organizations. Achieving these

certifications is the real measure of a company's quality

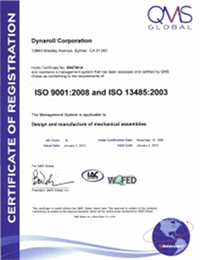

system. Dynaroll is proud to be certified to the following international

standards:

ISO 9001:2008 – the basic international quality standard requiring continuous improvements in systems of production control, product design, customer feedback, calibration, measurement and other areas affecting overall quality.

ISO 13485:2003 – a new standard for medical parts manufacturers requiring rigorous component and process traceability. This certification is held by very few companies in the USA and requires a sophisticated company-wide tracking system integrating all aspects of manufacturing operations.

ISO 14001:2004 – compliance with international environmental management requirements. All processes used at Dynaroll meet the strictest environmental standards.

OSHAS 18001:2007 – health and safety. All Dynaroll employees receive regular training in the latest health and safety practices. We provide the clean and safe working environment necessary to produce quality parts with a minimum of waste.

PPAP – Dynaroll is a PPAP-approved supplier to the automotive industry for parts used in GM, Toyota, Lexus and other fine automobiles. Our plants in Malaysia and China are also approved.

FDA Critical – Dynaroll is a qualified critical component supplier of parts to the medical industry. Our basic quality systems satisfy all FDA requirements for “critical” classification.

General Information on Dynaroll Quality System - The quality system at Dynaroll is an integrated system that flows easily with most industry standards for compatibility in all processes. Our instruments and metrological equipment fall under the auspices of ISO 17025 and we require all who supply calibration equipment or services to Dynaroll Corp to be approved by a third party to the same standard. The quality system at Dynaroll Corp is compatible with TS 16949 and AS9100 requirements and has all the necessary components of each standard.

Dynaroll Corp uses the ANSI Z1.4 standard for sampling and inspection and all instruments used for measuring are traceable to NIST (National Institute for Standards and Technology). First article inspection is performed to AS9102 and uncertainty budgets are established for all in-house standards, instruments, and processes and are based on the automotive industry action group (AIAG MSA-1). This standard is also used for gauge R&R studies. Calibration is tracked with the latest software technology.

Dynaroll Corp uses the latest in SPC software to control our processes and suppliers. We work closely with our suppliers and customers, using a team effort to obtain the customer’s desires.

Dynaroll Corp has uses risk assessment guidelines of the ISO 14971 standard during the design control phase of work.

ISO 9001:2008 – the basic international quality standard requiring continuous improvements in systems of production control, product design, customer feedback, calibration, measurement and other areas affecting overall quality.

ISO 13485:2003 – a new standard for medical parts manufacturers requiring rigorous component and process traceability. This certification is held by very few companies in the USA and requires a sophisticated company-wide tracking system integrating all aspects of manufacturing operations.

ISO 14001:2004 – compliance with international environmental management requirements. All processes used at Dynaroll meet the strictest environmental standards.

OSHAS 18001:2007 – health and safety. All Dynaroll employees receive regular training in the latest health and safety practices. We provide the clean and safe working environment necessary to produce quality parts with a minimum of waste.

PPAP – Dynaroll is a PPAP-approved supplier to the automotive industry for parts used in GM, Toyota, Lexus and other fine automobiles. Our plants in Malaysia and China are also approved.

FDA Critical – Dynaroll is a qualified critical component supplier of parts to the medical industry. Our basic quality systems satisfy all FDA requirements for “critical” classification.

General Information on Dynaroll Quality System - The quality system at Dynaroll is an integrated system that flows easily with most industry standards for compatibility in all processes. Our instruments and metrological equipment fall under the auspices of ISO 17025 and we require all who supply calibration equipment or services to Dynaroll Corp to be approved by a third party to the same standard. The quality system at Dynaroll Corp is compatible with TS 16949 and AS9100 requirements and has all the necessary components of each standard.

Dynaroll Corp uses the ANSI Z1.4 standard for sampling and inspection and all instruments used for measuring are traceable to NIST (National Institute for Standards and Technology). First article inspection is performed to AS9102 and uncertainty budgets are established for all in-house standards, instruments, and processes and are based on the automotive industry action group (AIAG MSA-1). This standard is also used for gauge R&R studies. Calibration is tracked with the latest software technology.

Dynaroll Corp uses the latest in SPC software to control our processes and suppliers. We work closely with our suppliers and customers, using a team effort to obtain the customer’s desires.

Dynaroll Corp has uses risk assessment guidelines of the ISO 14971 standard during the design control phase of work.